Reconditioning is much more

than just a cost-effective solution

than just a cost-effective solution

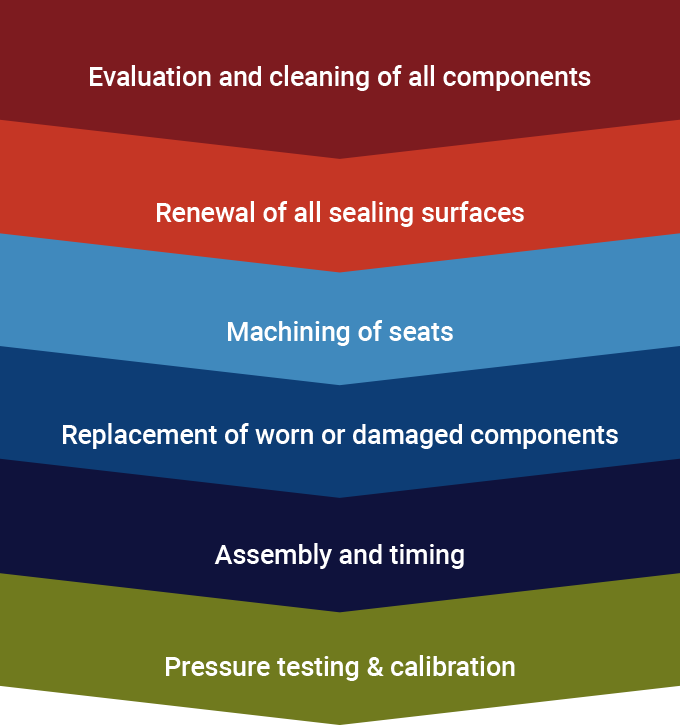

Reconditioned parts, which are fully tested prior to shipping to the end user, allow savings of up to 75% of the cost of new components and provide an alternative to a new part when lead times are too long or the component is no longer available.

Reconditioning services –

with real cost benefits

with real cost benefits

Fluid Mechanics LLC provides diesel engine reconditioning service for a limited number of components.

Reconditioning can save up to 75% of the cost of new components and, just as importantly, it provides an alternative to a new part when lead times are too long or the component is no longer available on the market.

The following components can be reconditioned:

- Fuel injection pump housings

- Fuel injection pump covers

- Fuel injector pump bodies

- Fuel injector nozzles

- Cylinder heads

- Valve cages

Diesel engine rebuild services –

to exact OEM specifications

to exact OEM specifications

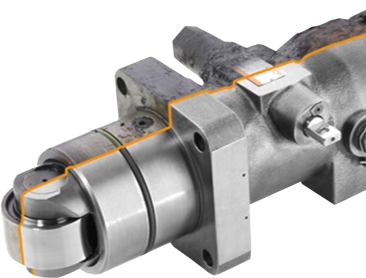

Fluid Mechanics LLC offers rebuild services for all the products we represent. These products are rebuilt to OEM specifications using genuine or reconditioned parts.

Reconditioned parts are used to reduce costs for the end-user. They are fully tested prior to shipping to the end-user.

We offer rebuilds for:

- Fuel injection pumps

- Fuel injectors

- Cylinder heads

- Exhaust valve cages

- Air start valves

- Safety valves

- Air & hydraulic starters

- Accumulators

Any questions?

We will be happy to answer any questions you may have. Just let us know what you are interested in and one of our representatives will be in touch with you soon.

Ohio +1 440 961-1120

Florida +1 954 525-1755

Similar tolerances as for new parts

No compromises on quality

Calibration and functional test

Injectors prepared for testing

New and reconditioned components

Staged connectors

Test stand set-up

Staged pump housings